Electric Cable Cover

Price 16 INR/ Number

Electric Cable Cover Specification

- Purity

- 98%+ virgin polymer

- Usage

- Protects underground cables from mechanical damage and warning for excavation work

- Color

- Yellow

- Material Grade

- Virgin grade HDPE

- Form

- Solid slab

- Features

- Chemical resistant, corrosion proof, lightweight, anti-corrosive

- Installation Type

- Directly on cable trench/cable route

- Machines Type

- Manual and automatic installation support

- Thickness

- 6 mm (can vary)

- Application

- Industrial, commercial, and electrical infrastructure projects

- Load Capacity

- High, suitable for vehicle and pedestrian traffic

- Product Type

- Electric Cable Cover

- Main Material

- High-Density Polyethylene (HDPE)

- Surface Treatment

- Smooth finish

- Size

- 1000 mm x 250 mm (can vary)

- Weight

- 2.5 kg (approximate, depends on size)

- Feature

- UV resistant, impact resistant, non-conductive

- Shape

- Rectangular slab

Electric Cable Cover Trade Information

- Minimum Order Quantity

- 5000 Number

- Main Domestic Market

- Uttar Pradesh

About Electric Cable Cover

We have appointed a talented group of professionals. Our experts work hard to know the requirements of patrons. Together with this, our team members are in constant dialogue with the clients that help them cater to their exact needs.

Some of the professionals working with us are as follows:

- Engineers

- Quality Analysts

- Technicians

- Skilled and Semi-Skilled Workforce

- Sales and Marketing Executives.

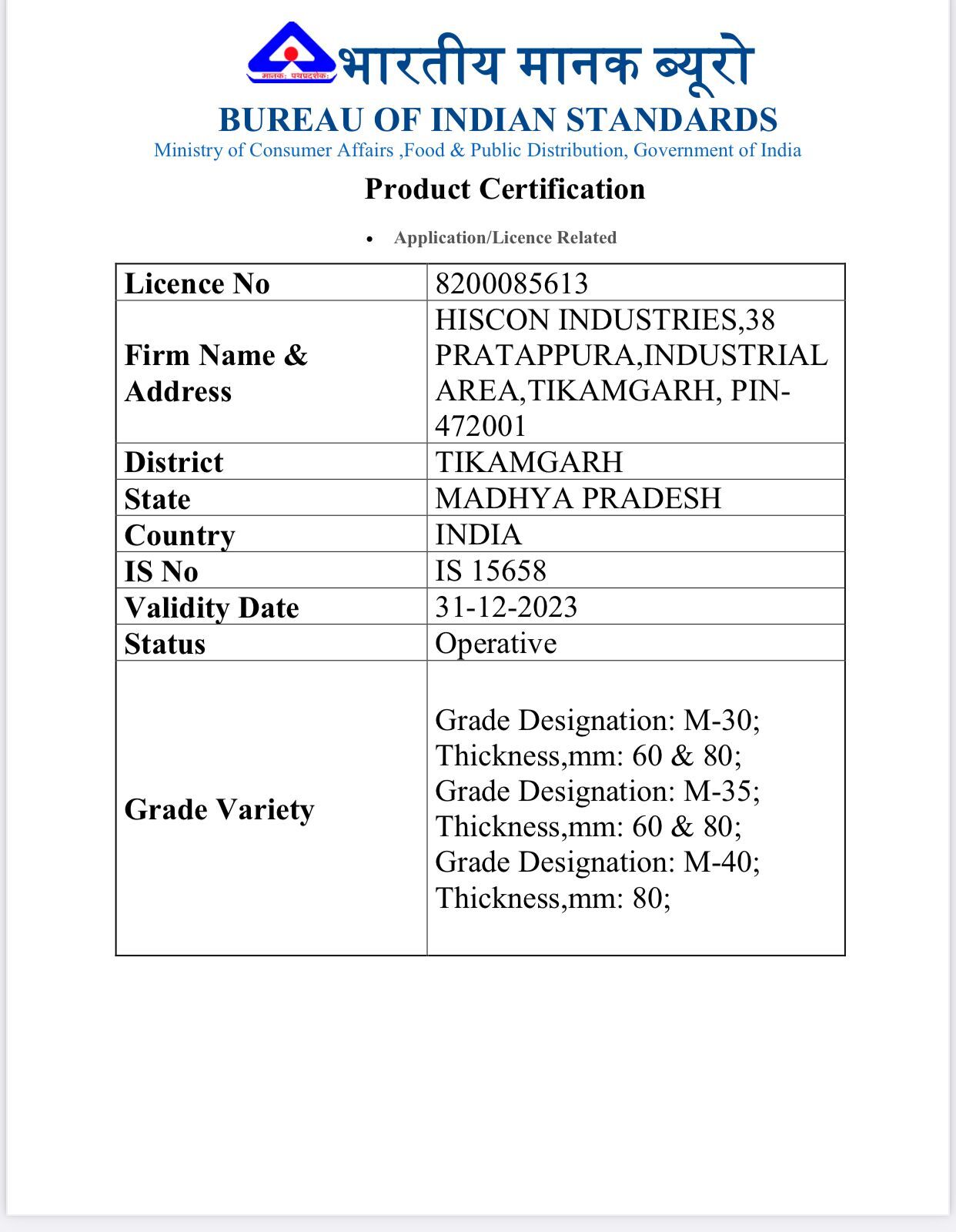

Certified Safety and Compliance

Manufactured in accordance with IS 14930 and ISO standards, these electric cable covers promise reliable performance and safety assurance. The high-density polyethylene (HDPE) material is non-conductive, highly resistant to chemicals and corrosion, and manufactured using more than 98% virgin polymer for purity. These features guarantee the product's suitability for strict regulatory environments.

Customisable and Versatile Design

Available in standard sizes or tailored to project specifications, each electric cable cover can be supplied with custom-moulded or printed warning messages. The bevelled or straight edges, smooth surface, and variety of width and thickness options enable seamless integration into diverse industrial and electrical infrastructure projects. The product's UV resistance and high durability ensure long-lasting, visible protection.

Engineered for Ease and Longevity

These cable covers are lightweight, stackable, and easy to install, supporting both manual and automated methods. Their robust build supports pedestrian and vehicular traffic, while the solid slab construction effectively shields cables from mechanical damage. 100% recyclability and low water absorption contribute to environmentally responsible, maintenance-friendly solutions for long-term underground cable protection.

FAQ's of Electric Cable Cover:

Q: How are these electric cable covers installed over underground cables?

A: These covers are designed for direct placement onto cable trenches along the cable route. Their lightweight and stackable form makes them easy to handle, and they support both manual and automatic installation processes, ensuring efficient deployment in various site conditions.Q: What customisation options are available for warning messages and sizes?

A: You can choose warning messages (such as 'Caution: Electric Cable Below') that are either moulded or printed onto the covers. Lengths can be standard (1000 mm, 1200 mm) or custom, with widths of 250 mm, 300 mm, 350 mm, and the thickness is adjustable to suit project needs.Q: When is it necessary to opt for fire retardant electric cable covers?

A: Fire retardancy is available upon request and is typically recommended for projects where additional fire safety is required, such as in sensitive electrical infrastructure or high-risk industrial areas where extra protection is critical.Q: Where can these electric cable covers be effectively used?

A: They are suitable for industrial, commercial, and electrical infrastructure projects, offering essential protection in locations subject to frequent excavation or heavy traffic. Their robust design makes them ideal for deployment along cable routes in demanding environments.Q: What advantages do these cable covers offer in terms of durability and maintenance?

A: Constructed from virgin grade HDPE, these covers are UV-resistant, chemical resistant, corrosion proof, and highly impact resistant, supporting both pedestrian and vehicle load. Their smooth finish and high density mean they require minimal maintenance and are highly durable even in harsh outdoor conditions.Q: How does the product's recyclability benefit the environment and project sustainability?

A: The electric cable covers are manufactured from 100% recyclable HDPE, ensuring that end-of-life slabs can be responsibly processed and reused, supporting sustainable construction practices and reducing environmental impact.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Madhya Pradesh, Uttar Pradesh

Pratapura, 37, Industrial Estate, Mauranipurorchha Road

Tikamgarh - 471010, Madhya Pradesh, India

Phone :08071793484

|

|

HISCON INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry